Protect your equipment with seals, O-rings and high-quality Polypack. We have more than 6,500 sizes in NITRILE, SILICONE, AND VITON.

About Us

Our family business was founded in the city of Iquique in 1976 by Orlando Soto Araya, and continued in 1980 under the leadership of María Inés Toledo Galindo, who became the first woman to sell spare parts in the city of Arica. In 2006, her son Orlando Soto Toledo took over foreign and domestic sales.

Since the beginning, we have been supplying the Armed Forces, fishing and mining companies in Northern Chile, as well as light and heavy-duty automotive fleet.

Did you know that seals are vital to prevent liquid, gas or solids leaks in your industrial equipment? From gearboxes to turbochargers, these silent guardians are critical to ensure safe and optimal operation.

Seals technical specifications

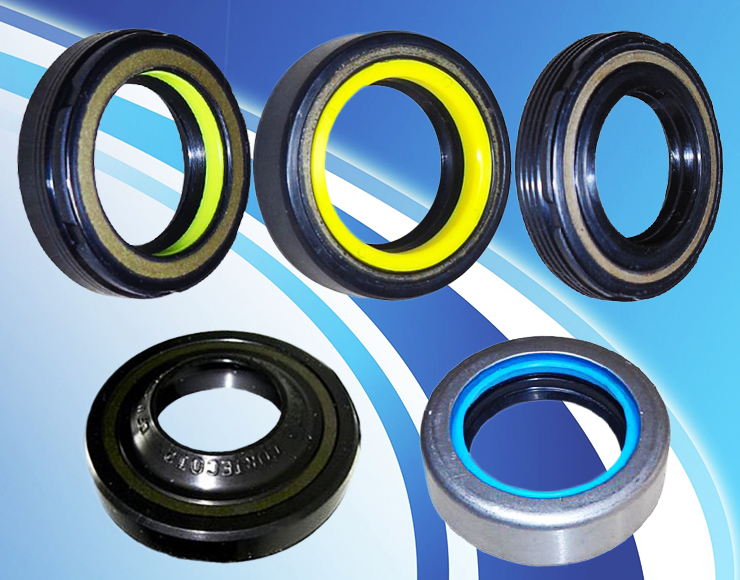

The seals include key components:

- Primary lip: Responsible for the seal, in direct contact with the moving part.

- Metal ring: Provides consistency and facilitates assembly.

- Spring: Ensures constant tightening between the primary lip and the shaft.

- Secondary lip: Prevents contamination of the retaining lip.

We have more than 6,500 sizes from brands such as (with interiors ranging from 4.8 mm to 340 mm):

USA CR – National- Federal Mogul

Europe STEFFA – MACO – CORTECO

South America SAV SABO DBH

Japan NOK – NAK – PAYEN – TTO

Taiwan WLK

Materials and characteristics of the seals

Seals are made from a range of materials, each adapted to specific conditions:

– Nitriles (NBR): Ideal for regular temperatures and standard lubrication.

– Polyacrylics (ACM): Resistant to high temperatures and additives.

– Silicones (VMQ): Recommended for high performance and high temperature applications.

– Fluorinated elastomers (FPM/Viton): Highly resistant to chemicals and high temperatures.

– Teflon (PTFE): Designed for dry conditions, with low friction coefficient and excellent fluids resistance.

Polypack technical specifications:

Polypack is injection-molded in polyurethane and then impregnated with molybdenum disulfide providing:

– Stable water and abrasion resistant.

– Withstands temperatures from -50°C to 120°C and pressure up to 400 kg/cm2.

– Ideal for hydraulic cylinders thanks to its mechanical resistance.

Characteristics of the

O-Rings and D-Rings:

– O-rings are versatile, providing static and dynamic sealing under various conditions.

– Available in a wide range of sizes and compounds, they are affordable and require little space.

– D-rings provide exceptional sealing in static, reciprocating, and oscillating radial applications, with added stability thanks to their rectangular base.

– Machined to prevent leaks and provide a cost advantage compared to molded seals.

– Adapted for automotive and heavy-duty applications, guaranteeing an efficient and drag-resistant seal.

Mechanical seals and retainers are the first line of defense of your industrial equipment, ensuring efficient and leak-free operation. With a wide variety of materials and designs adapted to different conditions, they guarantee the protection and durability of your critical assets. Be sure to choose the right ones to keep your equipment in optimum working condition.